Interesting article found at http://www.engineeringtoolbox.com:

Stable combustion conditions requires the right amounts of fuels and oxygen. The combustion products are heat energy, carbon dioxide, water vapor, nitrogen, and other gases (excluding oxygen). In theory there is a specific amount of oxygen needed to completely burn a given amount of fuel. In practice, burning conditions are never ideal. Therefore, more air than ideal must be supplied to burn all fuel completely. The amount of air more than the theoretical requirement is referred to as excess air.

Power plant boilers normally run about 10 to 20 percent excess air. Natural gas-fired boilers may run as low as 5 percent excess air. Pulverized coal-fired boilers may run with 20 percent excess air. Gas turbines runs very lean with up to 300 percent excess air. Stable combustion conditions requires the right amounts of fuels and oxygen. The combustion products are heat energy, carbon dioxide, water vapor, nitrogen, and other gases (excluding oxygen). In theory there is a specific amount of oxygen needed to completely burn a given amount of fuel. In practice, burning conditions are never ideal.

Therefore, more air than ideal must be supplied to burn all fuel completely. The amount of air more than the theoretical requirement is referred to as excess air. Power plant boilers normally run about 10 to 20 percent excess air. Natural gas-fired boilers may run as low as 5 percent excess air. Pulverized coal-fired boilers may run with 20 percent excess air. Gas turbines runs very lean with up to 300 percent excess air.

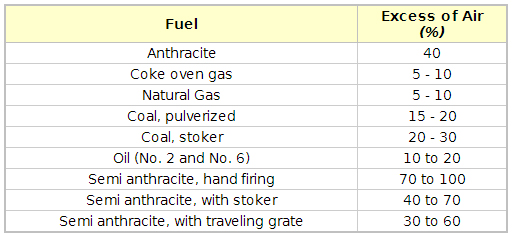

Typical values of excess air for some common fuels are shown in the table below: